I. Project background

As the company grows and develops, the requirements of customers for delivery and quality continue to increase, and the requirements of the market environment for cost and so on continue to increase. The senior management of the company clearly recognized that there are still many problems in the management of the company:

1. The company's employee basic management 5S has poor awareness, lack of theoretical knowledge, and arbitrarily large work, resulting in frequent product quality problems;

2. Process separation and separation Lean production management is wasteful in inventory;

3. The long-distance transportation across the factory is very serious. The phenomenon of transportation waste in lean production is obvious, and the overall layout planning adjustment is needed.

4. During the manufacturing process, the material is placed on the ground and needs to be transported to the turnover car again. The frequency of the transfer process is very high. It is necessary to set the handling items to reduce the frequency of handling;

5. On-site quality control has not set up effective management standard documents, and the quality is abnormally stable. It is necessary to establish an effective quality control system in the process;

6. On-site visualized data management and control is basically not available, and it is impossible to achieve on-the-spot and timely and effective control;

7. The scene environment does not realize the phenomenon of exhibition hall, and it is impossible to realize the change of employees by the scene (for example, the difference between a small hotel and a five-star hotel). The reliability of the customer will also decrease;

As a result, the company decided to dock with Ningbo Dia Industrial Equipment Co., Ltd. to carry out a lean on-site improvement management consulting project.

2. Customer needs

Chairman:

1 on-site waste improvement and reduction

2 exhibition hall to create on-site

3 on-site visual management implementation

4 employee awareness changes

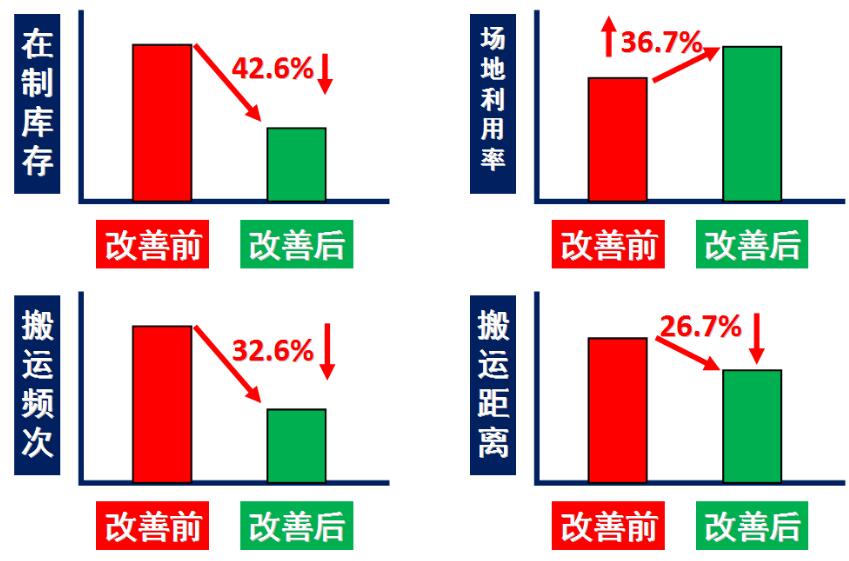

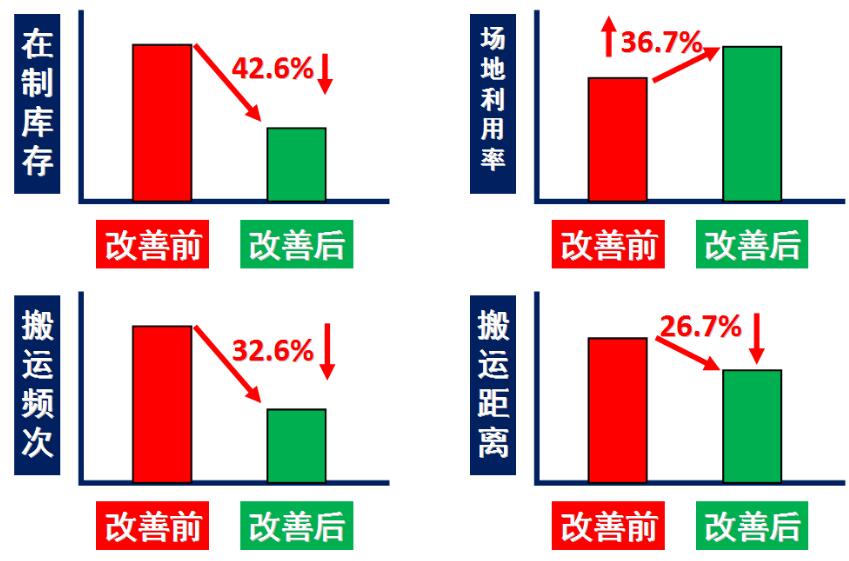

Improve the goal:

1 smooth layout to create

2 exhibition hall to create on-site

3 Site utilization increased by more than 30%

4 handling frequency is reduced by more than 20%

5 handling distance is reduced by more than 30%

6 Reduced inventory by more than 30%

3. Project improvement

Before improvement

Improved

四.Improving the effect

Wechat QR code

Wechat QR code