Intelligent storage

In addition to the comprehensive material management function, the most mature intelligent warehousing solution in China has:

Dynamic counting: support "multi person + different place + simultaneous" counting, which can be recorded in and out of the warehouse at the same time. Counting is very intuitive.

Dynamic inventory: reappear the inventory situation in historical period, convenient for financial audit.

Doc confirmation: after receipt, issue and transfer documents are prepared, confirm to update the inventory.

RFID handset Management: use handset for document confirmation, inventory, query and statistics.

Location management: RFID is associated with No. 4 location (shelf level).

Quality inspection management: registration of forced inspection items, warehousing quality inspection confirmation, and external inspection notice.

Full lifecycle management: materials from the warehousing to the outbound to the end of the process of management.

Project management: Party A supply management for individual projects.

Approval of required material purchase plan: approval authority, approval process, receipt notice, unlimited approval level.

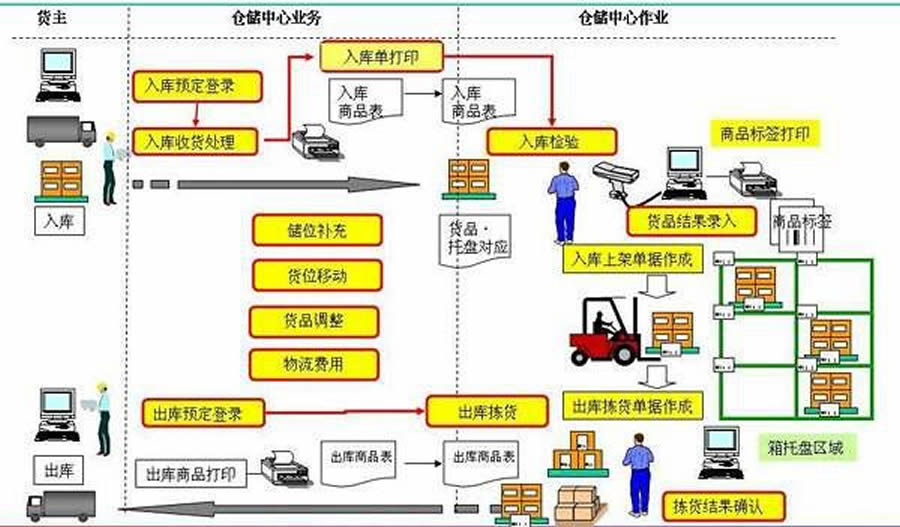

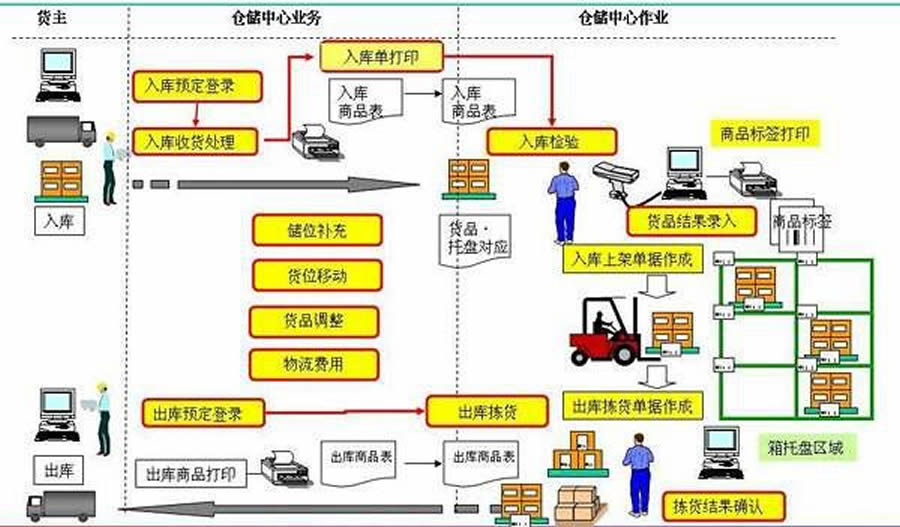

Brief introduction Intelligent storage is a link in the logistics process. The application of intelligent storage ensures the speed and accuracy of data input in each link of goods warehouse management, ensures that enterprises can master the real data of inventory timely and accurately, and reasonably maintain and control the enterprise inventory. Through scientific coding, it is also convenient to manage the batch and shelf life of goods in stock. By using the location management function of snhges system, we can master the current location of all goods in stock in time, which is conducive to improving the efficiency of warehouse management.

Establish

The establishment of an intelligent storage system needs the full support of the Internet of things. In the modern storage system, not only the items are complex, the forms are different and the performances are different, but also the operation process is complex. There are not only storage, but also movement, sorting and combination. Therefore, the intelligent logistics center with warehousing as the core often adopts intelligent technologies such as automatic control technology, intelligent robot stacking technology, intelligent information management technology, mobile computing technology, data mining technology, etc. In these cases, the application of the Internet of things can be simplified and greatly improve the efficiency of the whole logistics distribution.

Application characteristics

In the application of the domestic Internet of Things, there are mainly several aspects of the characteristics: First, the application of sensing technology is relatively good. The most popular IoT-aware technology in China's warehousing industry is RFID technology. In some advanced warehousing and distribution centers, RFID tags and smart radio frequency (RF) handheld terminals have a wide range of applications. This is because RFID technology is combined with the pallet system and closed-loop application in the warehouse distribution center can effectively reduce costs. We also know that in the ordinary storage system, in addition to the wide application of bar code-based automatic identification technology, the "electronic tag assisted picking system" also has certain applications. The so-called electronic tag here refers not to an RFID tag, but a system that uses an electronic indicator tag for picking operations. With this system, the inbound and outbound orders are decomposed by the computer system, transferred to the shelves of various positions, and the electronic picking technology is used to guide the picking and assisting picking system. This system is simple and practical, and has a wide application.

According to some reports in 2010, a system based on auxiliary voice sorting has also been applied in China. With the help of wireless network and headphones on the picker's head, send the picking instruction to the picker to complete the picking operation. This technology still looks cool.

Development prospectThe biggest trend of modern logistics is network and intelligence. In manufacturing enterprises, modern warehousing and distribution centers are often integrated with enterprise production systems. As a part of the production system, warehousing system plays a very important role in enterprise production management. Therefore, the development of storage technology is not separated from the business of the company, and the integration and cooperation with other links will be more conducive to the development of the storage industry.

Wechat QR code

Wechat QR code