How to manage production resources is the key to the strategic development and competitiveness of enterprises. Lean operation management is a management activity oriented to production resources. It designs and controls enterprise system and optimizes operation process through lean operation management, so as to effectively utilize human resources, raw materials, equipment, facilities and information in the production process of products or services, and win competitive advantages in cost, quality, service and speed.

Jinhaiyuan lean operation is positioned to provide comprehensive solutions for performance improvement of enterprises. We take the improvement of enterprise performance as the goal, from three aspects of strategy, operation and management support system to transform and promote, systematically solve all kinds of manufacturing transformation performance problems faced by enterprises. for example:

· The production and operation lacks medium and long-term strategy.

· Production and operation are oriented by their own needs rather than the needs of market customers.

· The production and operation system pursues the interests of individual departments rather than the best interests of the whole system.

· The process of creating value cannot be defined and identified accurately, and resource allocation is based on department needs rather than process needs.

· The production and operation process and system are lack of standardization, and the ability of continuous learning and improvement of the organization is lack.

· The business process is chaotic and the operation efficiency is low.

· The waste of enterprises is serious and the cost is high.

· The quality system is not stable and perfect, which can not guarantee the consistency and reliability of product quality.

· Product quality depends on inspection, not manufacturing process itself.

· The production system lacks flexibility and is difficult to meet the requirements of delivery time.

· The product inventory is too high and the capital turnover is difficult.

· The product development and production cycle is long, and the response to the market is slow.

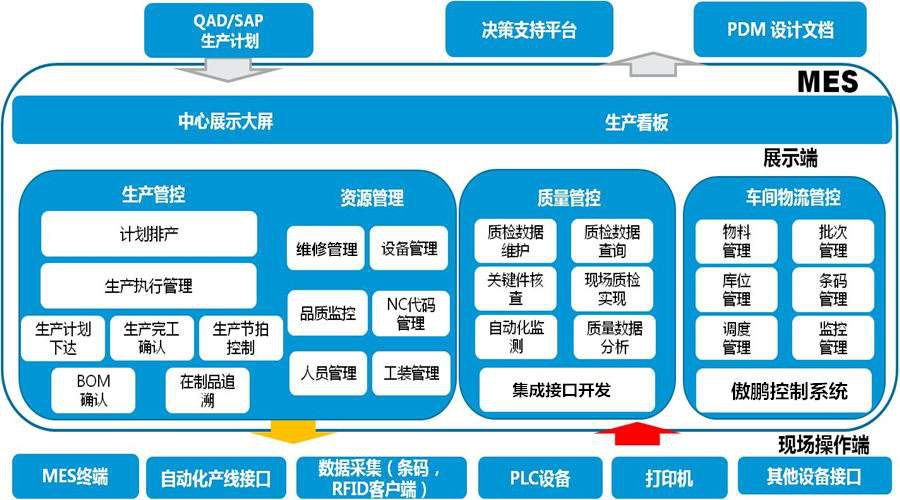

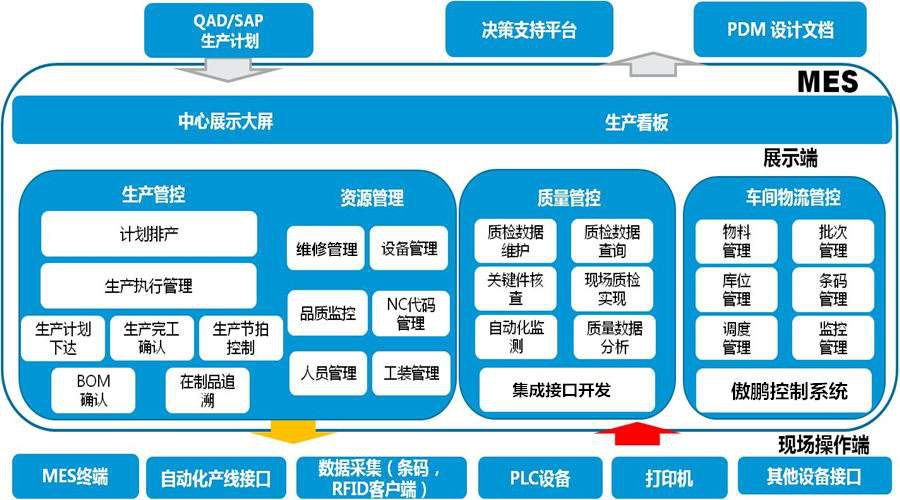

· Information system is out of line with business process and becomes information island.

· The lack of lean production, standardization and modularization affects the introduction of automation.

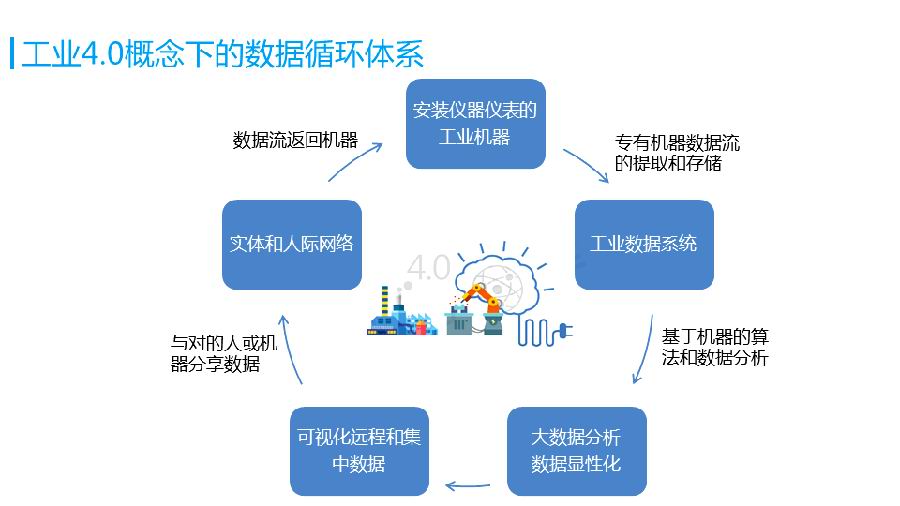

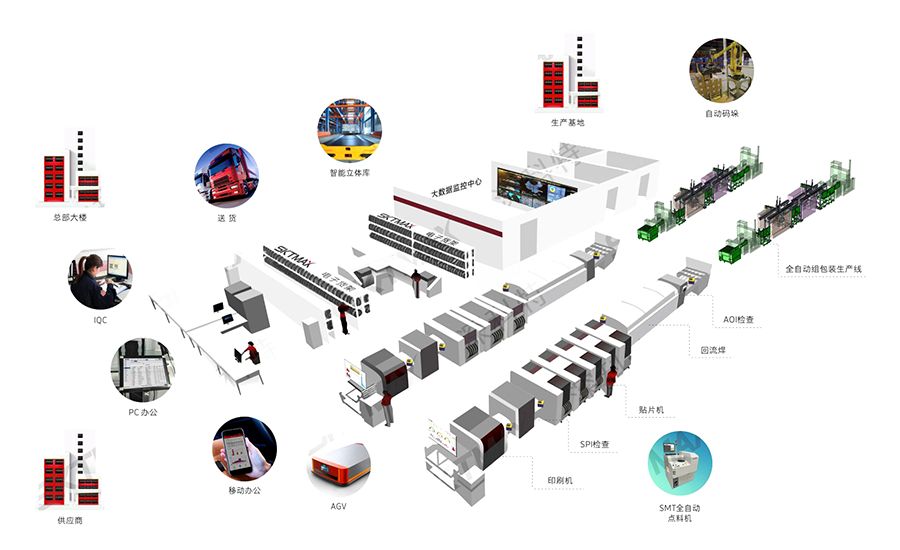

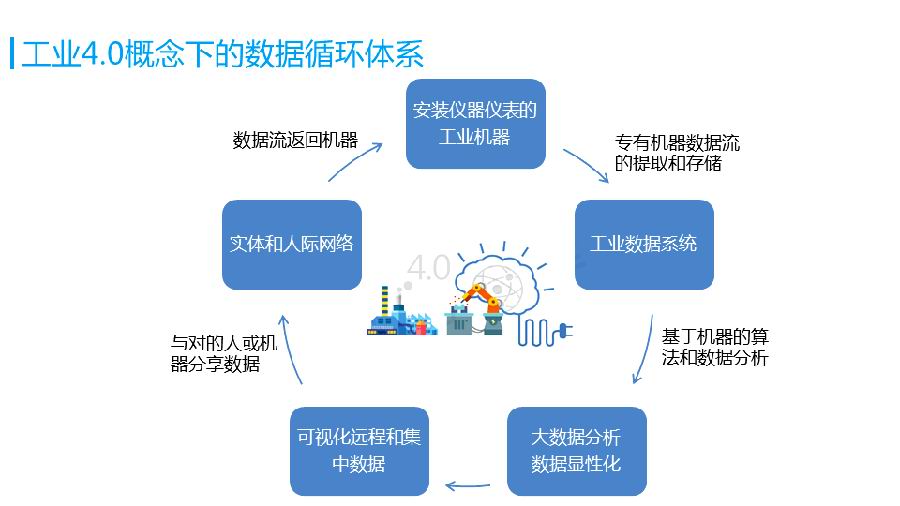

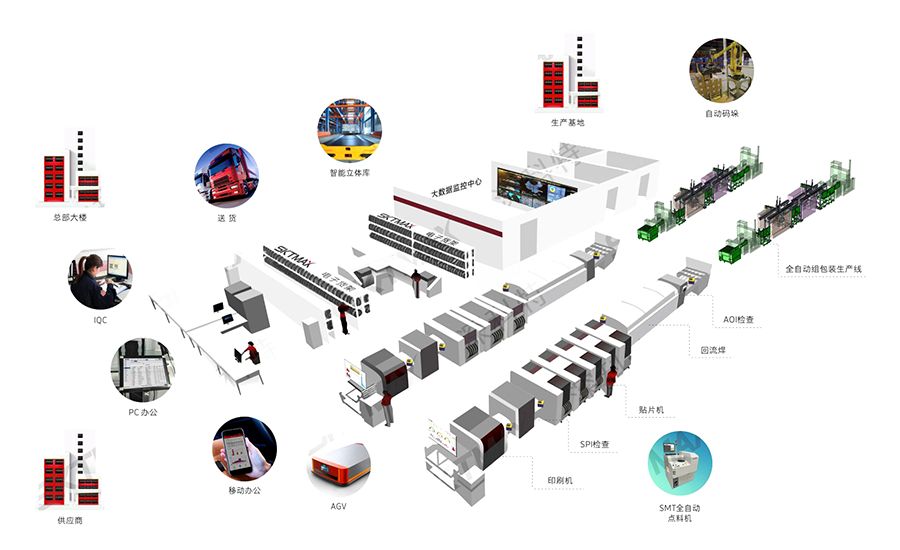

· Production process, automation equipment and information system are independent, so they are difficult to integrate into intelligent manufacturing.

In view of the lack of effective management tools in domestic enterprises, jinhaiyuan lean operation refines and develops the management tools and technologies that are widely implemented and have achieved effective results in European, American and Japanese enterprises. Combined with our research in various functions and industry fields, it has been successfully applied in the management practice of domestic enterprises.

Jinhaiyuan lean operation solutions include: strategic planning and operation, lean production / service, supply chain management, R & D and design, operation process, operation performance evaluation, site management, TQM of total quality management, TPM of total production and maintenance, six sigma, layout planning and design of logistics, etc.

Wechat QR code

Wechat QR code